Our offer

The power hydraulics division

Our power hydraulics department is a leading centre specialising in the design and implementation of complex power hydraulics systems. Our services are always tailored to the individual needs of the client, so that we deliver solutions that meet their expectations and, of course, their technical requirements.

Each project starts with a detailed analysis of the technical documentation provided by the customer or developed by our team of experts from our own design office. This collaboration ensures a full understanding of the project objectives and specific technical requirements, which is key to achieving optimal results.

Departmental equipment

- Doosan PUMA 5100XL lathe, max workpiece dimensions Ø650mm x 3082mm

- TR1-72 CNC PORĘBA, max workpiece dimensions Ø740 x 4000mm

- TRP 63 MN PORĘBA, max workpiece dimensions Ø650 x 3000mm

- SPT32NC MAS, max workpiece dimensions Ø280 x 1350mm

- SDM12 HEID, max workpiece dimensions Ø531x1000mm

- TK-610 CNC JANUS - max workpiece dimensions Ø610x1900m

- HURCO BMC 50/50M ULTIMAX 3 machining centre - max workpiece dimensions 750x2000x600mm, max workpiece weight 1497kg

- Machining Centre HURCO VM10i Plus - max workpiece dimensions 762x406mm, max workpiece weight 1500kg

- Machining centre HURCO VMX84i SK50 with WinMax control - max workpiece dimensions 2185x865mm, max workpiece weight 2270kg

- Honing machine Sunnen HTS-074-020 - honing of tubes with diameter min Ø76 - max Ø450 with length up to 2500mm

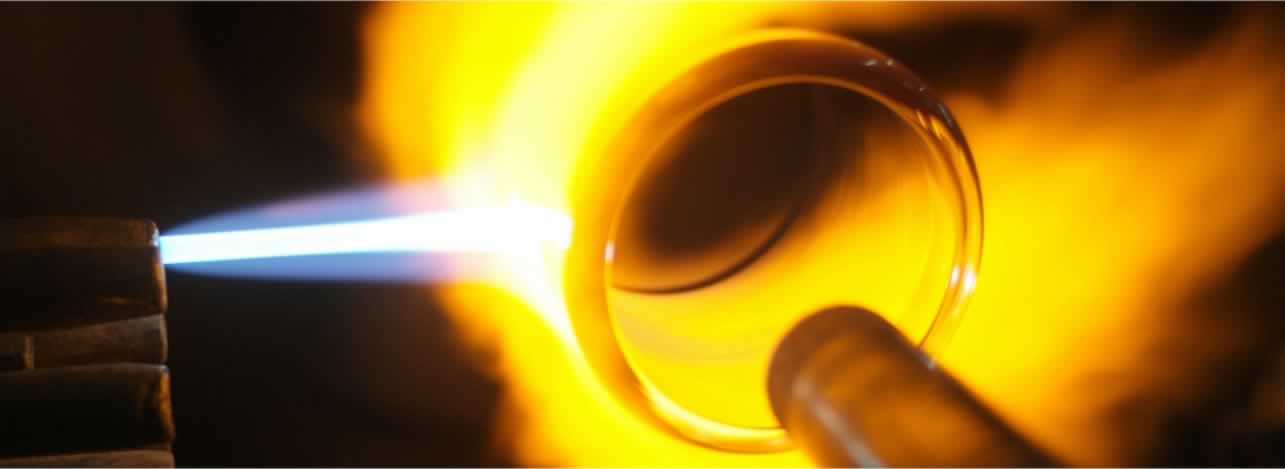

- Hardening furnaces: WPA 80x150, PEGAT 700/4, PEGAT 700/2 - heat treatment in the field of: hardening, tempering, workpieces made: Bars and tubes max 1500mm in length in steel grades: 32HA, 41Cr4, 35HGS, 42CrMo4

- CNC long-hole drilling machine SHIN-IL SMGB 1500 - drilling of holes from min Ø3 - max Ø32 with length up to 1500mm

- Behringer HBE 411a band sawing machine

Construction department

The Energy and Welded Structures Division is the cornerstone of our business, combining high-calibre specialists with a state-of-the-art machine park. Our production capabilities range from the manufacture of pressure equipment to a variety of structural components for the energy, mining, metallurgy, chemical and food industries.

Amongst other things, we offer:

- Manufacturing of equipment subject to European directives with the required CE safety mark, such as pressure vessels and process piping.

- Manufacture of components for overhauled or modernised equipment subject to directives and UDT supervision, including assemblies and components for steam and water boilers, non-pressure vessels for hazardous materials, and pipeline components of various types.

- Production of steel structures in the field of construction, machinery, equipment, process pipelines, including bent structural elements and flue gas and air installations.

Department equipment

- Welding machines

- Gas welding machines - STATOSEC P4600/OMICOM, ZINSER CNC 4010

- Plasma cutting machine - CNC controlled VX

- Beveling robot - NS 12 ARC Comau

- Cutting machine IK-93T HAWK KOIKE - IK 12 Beetle Koike

- Plate rolling machine - XZC 3000/25

- Pipe bending machines - WE 60, WE 100

- Press brake - LVD PP100/25-30

- Band sawing machine (cutting diameter up to Ø 500mm) Pilous ARG500Plus Bomar TRANSVERSE 510.330 DGH

- Radial and column drilling machines

- Numerically controlled boring machine - TOS WHN13CNC and TOS WHQ13CNC Table length 2500 mm, table width 1800 mm, max. table load 20000 kg

- Conventional boring machines - Defum AD125, boring and milling machine HWC 110, boring and milling machine 3TC 25635, max table size: 1500 x 1800 mm, max table load 10 tons

- Universal milling machines - max. detail 630 x 1800 mm

- Shotblasting chamber SciTeex, dimensions 7.7 x 3.9 x 2.9 (L x B x H) metres

- Painting chamber with dimensions 10 x 3,2 x 3,3 (L x B x H) metres

- Overhead cranes: 16T, 10T, 8T, 5T.